About JOEST Australia

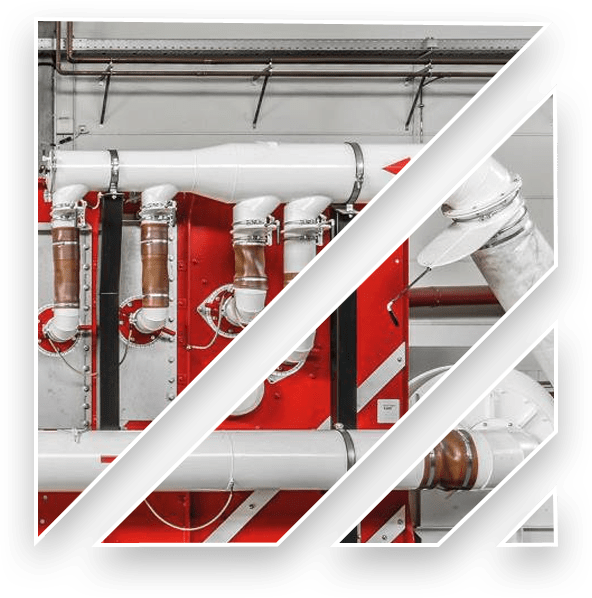

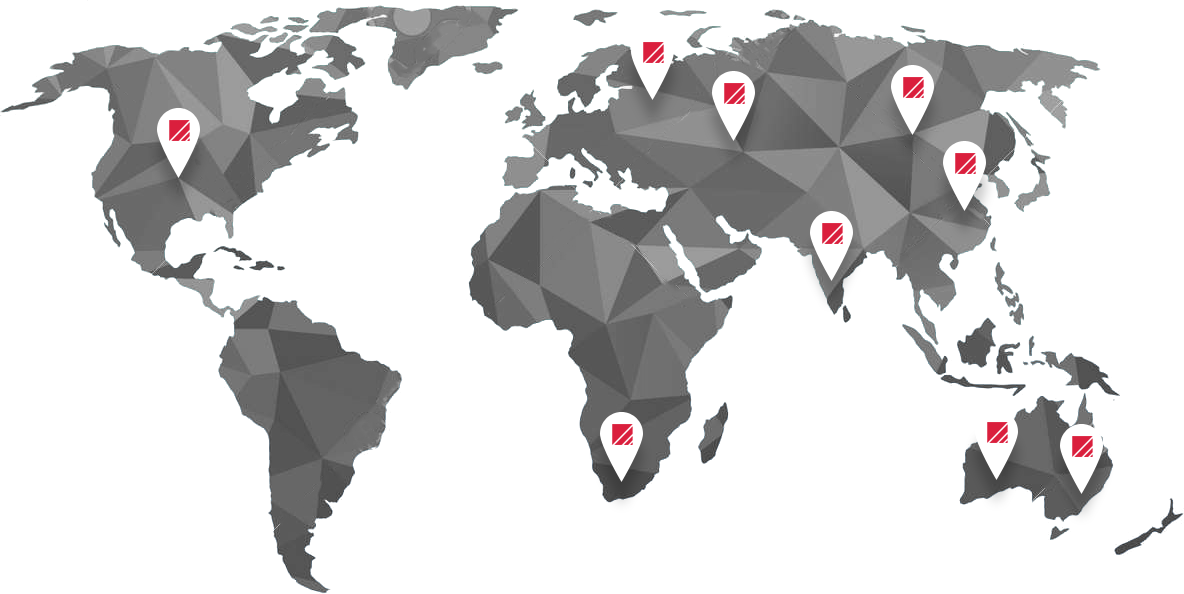

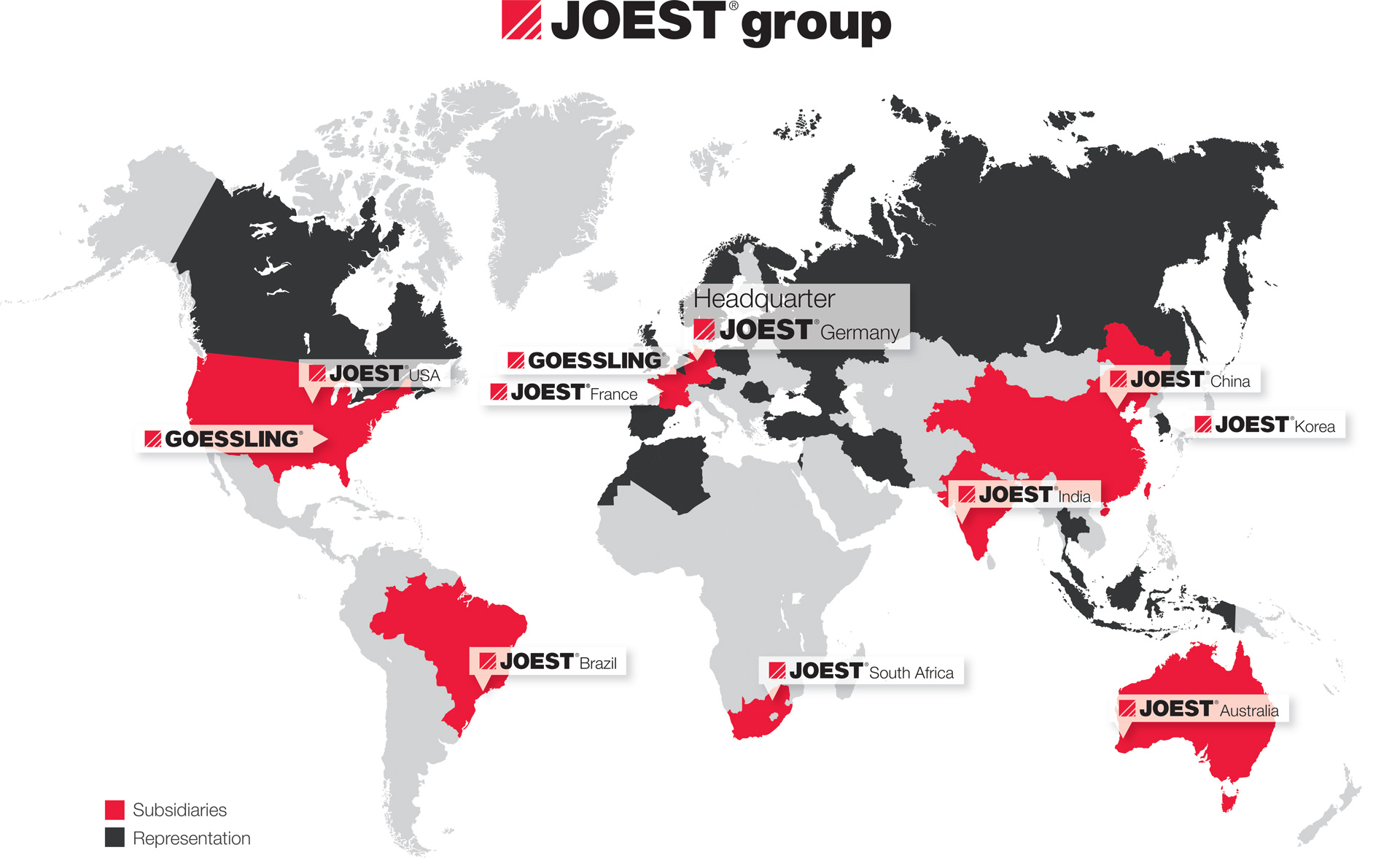

A leader in vibration technology worldwide for nearly a century, JOEST Group has subsidiaries with more than 850 personnel around the world. Our talented engineers are experienced in providing innovative and creative solutions for a wide range of problems – whether it’s with regard to screening machines, conveying or thermal processing.

JOEST continues to research and develop machines that will allow us to adapt to the growing demands of the market. Machines from JOEST are renowned to be highly reliable operation in all sectors of industry and all parts of the world.

Industries

JOEST Australia is a medium-scale enterprise that offers flexibility and industry-leading knowledge with regard to vibration solutions. With our workshop in Perth Western Australia, we are able to produce much of our equipment in Australia. We serve many industrial sectors such as:

Western Australia

Call +61 8 9358 3740

or fax +61 8 9358 3928

62 Coldwell Road,

Kenwick WA 6107

New South Wales

Call +61 2 4960 8694

or fax +61 2 4960 8694

4/2 Frost Drive Mayfield West 2304