JOEST Apprentices 2020

JOEST congratulates James Lynch on the successful completion of his trade apprenticeship Certificate III In Engineering – Mechan..

Read More

JOEST – Our new home

After a year in the design phase and a further 10 months of construction the JOEST team are now relocated into our new ‘State of..

Read More

New Home for JOEST Australia

The new home for JOEST Australia is nearing completion, the final details of the build are happening with the keys due to be hande..

Read More

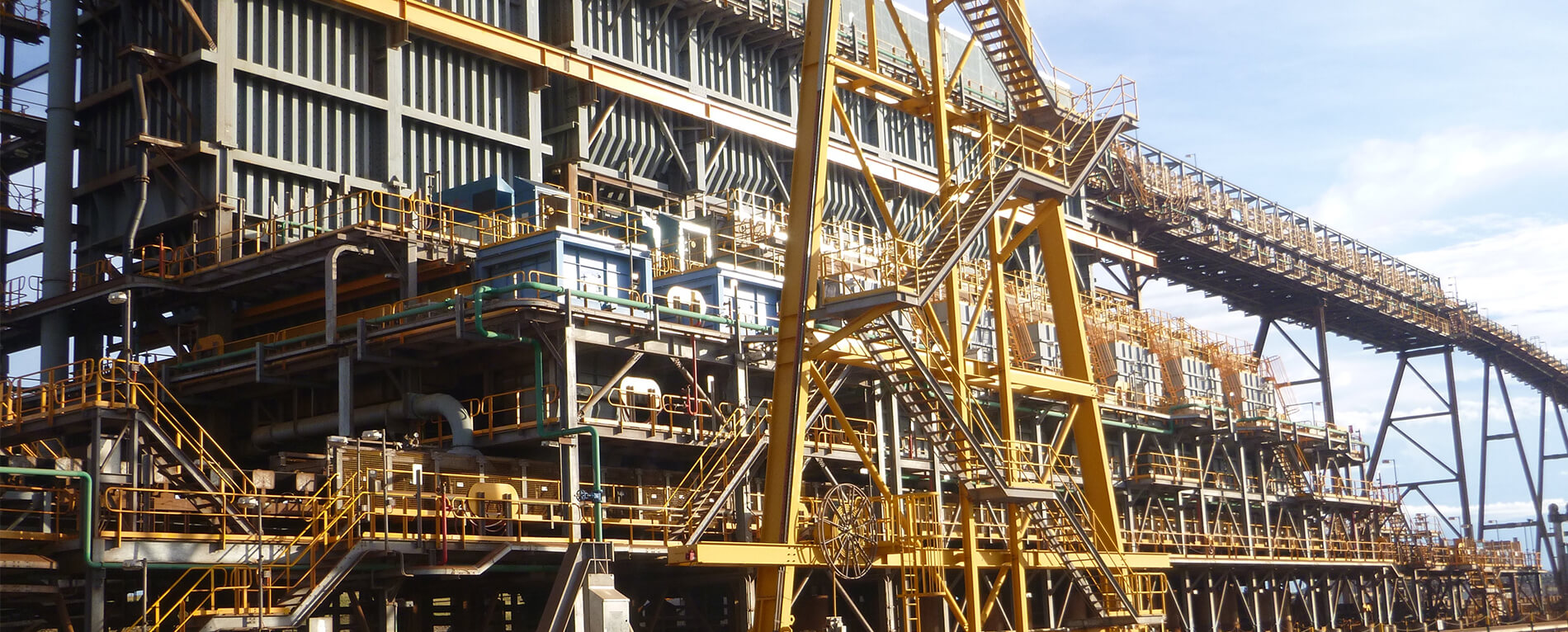

JOEST Vibration Technology utilised in plant upgrade for Pilbara iron ore producer

JOEST Australia Pty Ltd recently supplied two JOEST Vibrating Grizzly Screens (1 x Primary and 1 x Rotable) to Roy Hill Iron Ore P..

Read More

JOEST new building is at lock up stage

The excitement is definitely building as progress continues Office ceiling now in and cranes installed in locked up workshop..

Read More

Office Roof is on 8th June 20

We can feel the excitement building as the office roof is now on and the front fence is also up..

Read More

JOEST latest photos at Lot 35 Coldwell Rd

Progressing well and taking shape photos taken 18/04/2020..

Read More

Positive Energy

Michelle Chafin from the Engine Room said Excelerate business leader Ian Laws (far right) knows the value of investing i..

Read More

First Soil at Lot 35 Coldwell Road

Monday 2nd December 2019 at 8:30 am JOEST met with Tom Brooking (Brooking Design), Robert Biagioni (RBC) to turn the first soil on..

Read More

One Team working seamlessly to provide consistent solutions around the world

What are the signs of a truly integrated company working together on a global scale? Is it regular and open communications? Shared..

Read More

JOEST at ACPS 2018

JOEST Australia participated in the 2018 17th Australian Coal Preparation Society Conference held in Brisbane. Delegates and exhib..

Read More

The Next Step in Large Vibrating Screens

Following extensive design effort using JOEST Australia FEA methods, JOEST has commenced construction of a single deck screen 4.88..

Read More

JOEST Australia Grow their Manufacturing facilities

Following an increase in equipment sales, JOEST Australia has secured an additional workshop facility to enable machines to be bui..

Read More

JOEST Australia Strengthens Sales Team – April 2018

News for the JOEST sales team. JOEST Australia is pleased to welcome Marc Wellsted to join the Sales & Applications Engineerin..

Read More

JOEST Australia – Graduate Engineers 2018

Kevin Singh & Kyle Pedeferri (Kevin left & Kyle right) JOEST Australia has provided the opportunity for 2 young Curtin Eng..

Read More

Drying of Diatomite in Australia

JOEST to deliver drying plant and screening machine to Australia Agribusiness. An Australian customer, Agripower has a mineral dep..

Read More

JOEST at AWRE

JOEST Australia reinforced its presence in the recycling sector when exhibiting at the recent Australian Waste & Recycling Exp..

Read More

JOEST or JÖST?

We are often asked why the spelling of JOEST is sometimes JÖST, and whilst different both are correct, so long as the Ö includes..

Read More