Drying of Diatomite in Australia

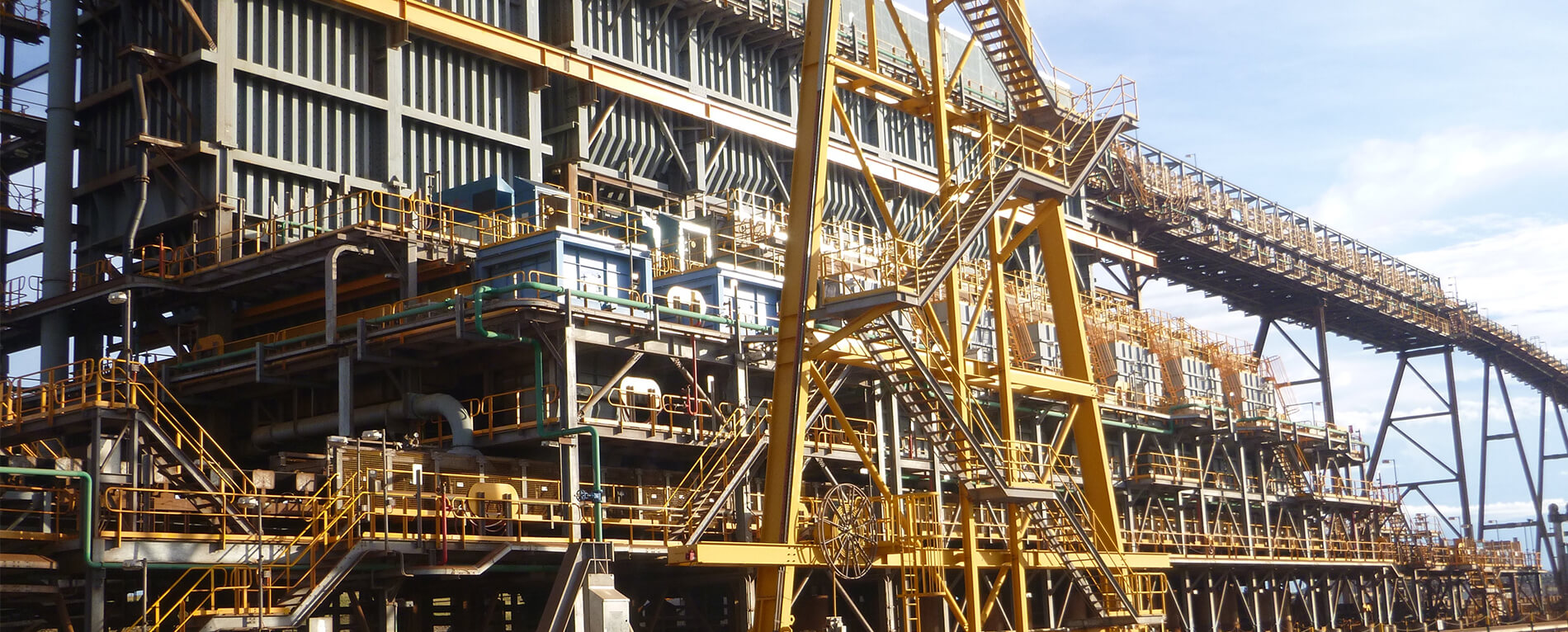

JOEST to deliver drying plant and screening machine to Australia Agribusiness.

An Australian customer, Agripower has a mineral deposit of diatomite and was looking for a solution to efficiently dry the granulated material, recover the evaporated process water and screen the diatomite after the drying process.

Diatomite are formed in fossilized shells of diatom. One ml of diatomite contains one billion shells or fragments of shells. The material is highly porous with a medium pore diameter of 0.2 – 10 µm. Water can infiltrate the pores and is hold against the gravity, plant roots cannot enter the pores but the water will be released easily due to the soil moisture tension. Due to these properties, diatomite is very suitable for use as a fertilizer.

The challenge was to take 40 t/h wet mass flow intake material from a mixing unit, 32 % moisture wb (wet base) at the dryer intake, 10 – 12 % or < 5 % moisture wb after dryer and the removing of lumps > 4 mm and fines < 2 mm. After the request for this large plant, JOEST engineers evaluated the drying properties with a series of laboratory tests, checked the process design and prepared a plant design according to the requirements. The result is a very efficient solution was proposed, and accepted by Agripower.

The drying plant will consist of two fluidized bed dryers with a width of 2.500 mm, and length of 8.800 mm each, a complete 44 m² blower stream section. The machines have a thermal power of 13.000 kW and the required process air is 150.000 m³. 2.500 m² filter surface for exhaust air filter and an exhaust air heat exchanger will be installed. Additionally, a double deck screen of 2.4m wide and 5.0m long and will separate the lumps and fines.

In 4th quarter 2017 the plant will be ready for delivery to Australia. With this solution, tailored specifically for the customers need, JOEST could once again provide an innovative system using first class German engineering, quality and reliability.