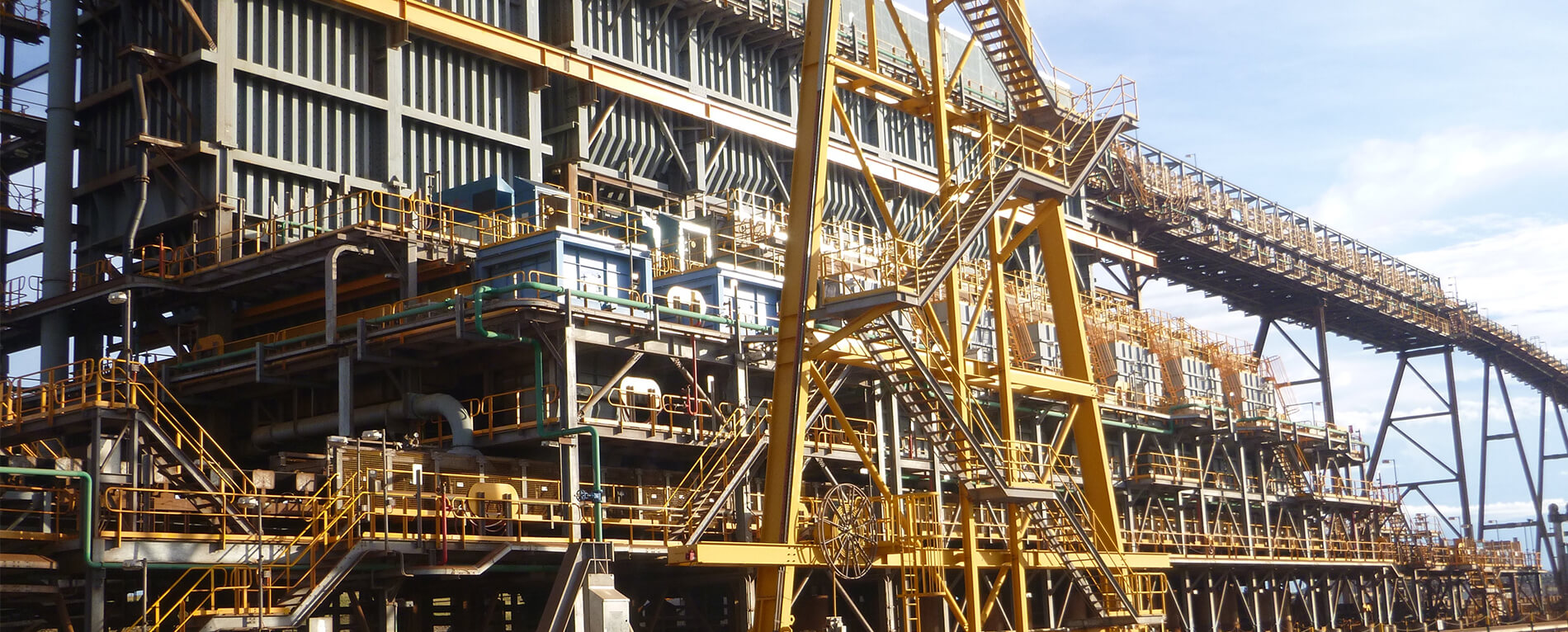

Drying

Fluidised Bed technology for Drying and Cooling applications

JOEST provides fluidised bed technology used in the agricultural, food, chemical and mining industries.

The JOEST vibrating Fluidised Bed Dryer uses convection to transfer heat energy through a fluidised bed of material to dry or cool a product. The method of drying involves transporting material through a stream of air, creating a fluidising bed that removes or adds moisture from or to the material. The forces within a Fluidised Bed Dryer are relatively low, allowing for minimal degradation of material as it passes through the vessel. Material transfer through the machine is provided by a vibrating drive system, and the systems can be designed for either heating or cooling applications. Typical system packages comprise of a heater or cooler, an air blower, air exhaust, filtration and control system.

Advantages / Features of Fluidised Bed Dryer technology:

• Thermally efficient process providing high air to material contact

• Heating and Cooling capability using zoned temperature control

• Uniform Material Discharge for temperature and moisture – ideal for temperature sensitive materials

• Vibration drive system used to optimise material transfer, retention time and product quality

For further information, please visit the website:

JOST Germany

Customised designs provide material solutions for temperature and moisture control.